Welcome to Tecnocupole Pancaldi, the story of people and an industrial sector that deals with smoke and heat exhaust systems, which were not always referred to as such.

1958

Gianni e Luigi Pancaldi

The Pancaldi brothers moved from the province of Ferrara to Bologna. Here they learned how to bend and transform plexiglass and build the machines required to work with it.

1960

The beauty of transparency

Plexiglas, Perspex, Lucite, Trespex, Vitroflex, Acrivill, Perclax, Limacryl, Crylux, Oroglas, Setacryl, Altuglas, polymethyl methacrylate has as many names as there are different compounds available on the market. Everyone likes it and it's in fashion. And if for most it is just plastic, for the Pancaldi brothers, rich in initiative, it becomes a business with capital letters. L&G Pancaldi is born.

1965

From signs to chandeliers, everything is illuminated

The Italian economy experienced a boom, and the home lighting sector was no exception.

Gianni and Luigi were no longer enough, the company was hungry for manpower and the first collaborators arrived, people who would remain with Pancaldi until retirement age.

1970-1980

From chandeliers to skylights

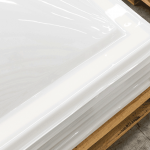

Industrial production has new enclosures, they are the warehouses. Concrete structures in need of light and air to make them welcoming. Glass is a limiting solution; it is heavy and not very versatile. Some plastics that yellow quickly prove to be inefficient. Plexiglass still offers only advantages: lightweight, transparent, and durable, it outperforms the competition.

1986

Innovations, investments and new opportunities

The product range, of a new concept, is taking shape, composed of openable domes for ventilation and no longer mono-block skylights. It is the evolution demanded by the industry.

Extruded methacrylate and compact polycarbonate are entering the market, and Tecnocupole Pancaldi invests in the first industrial thermoforming plant with manual loading and unloading to work with them. L&G Pancaldi becomes Tecnocupole Pancaldi Srl.

1989

A big change: the first UNI 9494

Domes and fire prevention, a debated and discussed topic on many national and international platforms. From this moment on, the dome is no longer considered solely as an illuminating and ventilation element but becomes an active component for fire prevention. Tecnocupole Pancaldi is at the forefront in this field.

1991

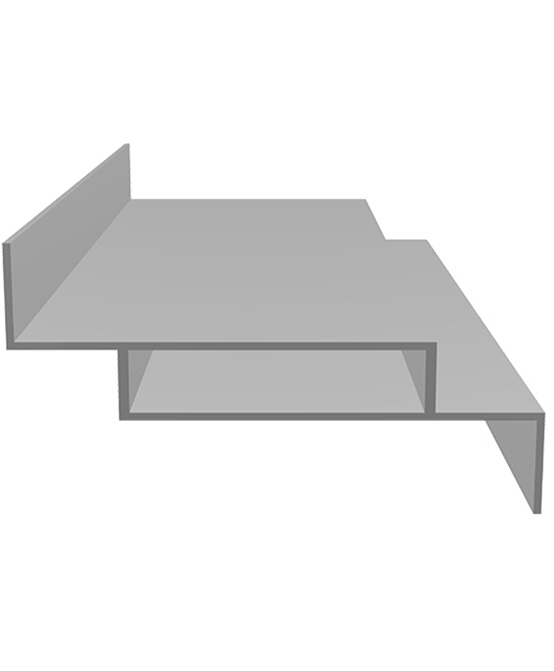

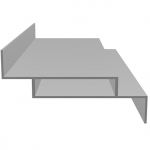

The Z-shaped frame profile

A simple aluminium extrusion that, after 30 years, demonstrates the value of Pancaldi's innovation, with its concealed fixing chamber that protects it from the elements. Still used in all types of openings to this day.

1992

Zenital, the pro-security association is born

Tecnocupole Pancaldi is one of the founding members of the Italian Association of Natural Lighting and Ventilation Systems, as well as Systems for Smoke and Heat Control

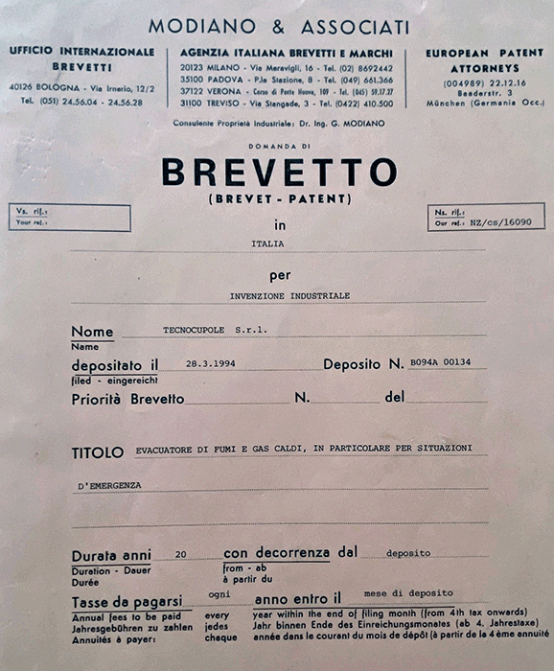

1994

The Free Smoke patent

Free Smoke is Tecnocupole Pancaldi's first patent. Numerous unsuccessful attempts have been made to copy it. Once again, the company's drive towards the future and its commitment to research and development are demonstrated, establishing it as a manufacturer of innovative NSHEV systems. One year after the patent, it becomes European with a duration of twenty years.

1996

The new advances

From Bologna to Castelguelfo, just a few kilometres for a significant change. It is the embryo of the production structure destined to become today's Tecnocupole Pancaldi. The first workshop for manufacturing aluminium frames, the machinery for processing sheet metal for the construction of skylight support bases. The technical office is strengthened. Professionalism and expertise are added to introduce new product visions such as "custom-made" skylights for every type of roof.

1997

The qualification that makes the difference

The laboratory authorized to perform tests in accordance with UNI9494:1989 is now a reality. Another step forward that heralds new product developments in the field of smoke and heat control systems.

2000

First steps of the new generation

Antonella, Elena, Laura, Michela. The daughters of the Pancaldi brothers make their entrance into the family business. Gianni and Luigi are there to welcome them and guide them through an experiential training journey: "to truly understand the product, one must experience it first-hand," and to reach great heights, it is best to start from the bottom.

2005

The evolution of the SHEV

EN12101-2 is now officially the European reference standard for smoke and heat exhaust systems, which are now subject to CE marking under the Construction Products Directive. Testing laboratories will have to start over from scratch.

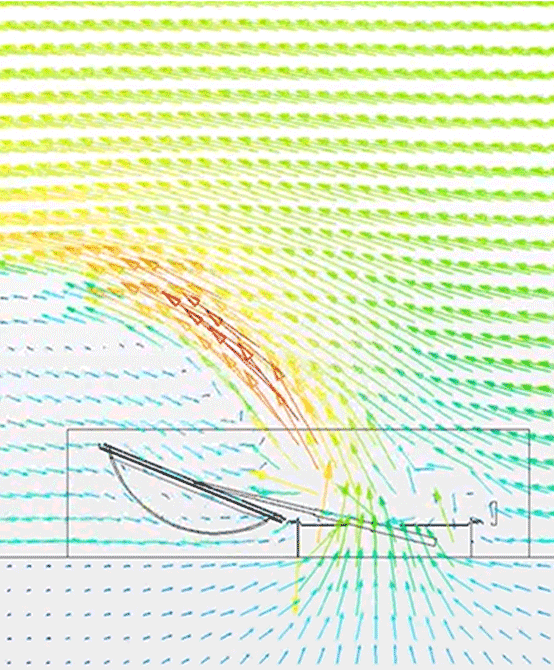

Tecnocupole Pancaldi initiates a collaboration with UNIBO that will lead to the development of tools for conducting qualification tests for NSHEV systems according to the new standard.

2007

50 years

Transformation into a joint-stock company (SPA) and new production infrastructure constitute the "gift" for this anniversary. "Lean production" is the new production philosophy, and the steps required to create a skylight from scratch are truly counted. Specifically, it takes 110 steps.

2010

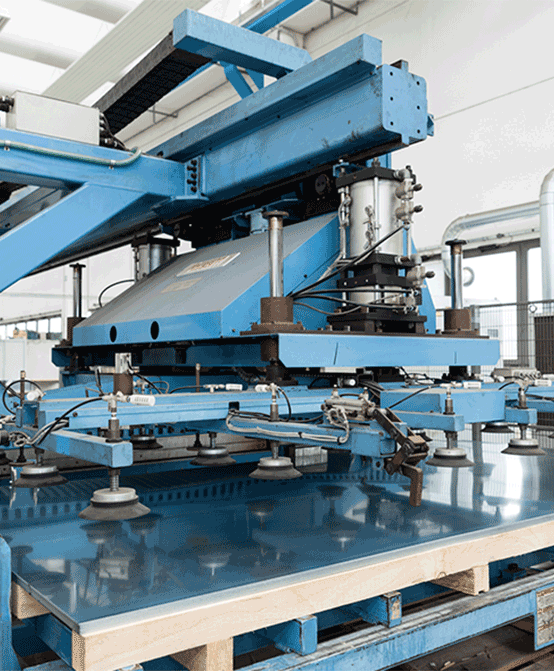

Investing again

The themes of energy saving, and thermal insulation represent specific market needs that require a prompt response. A new and modern thermoforming plant makes its entrance into the 6,000 square meters of production space. And thus begins the diversification of the product range.

2013

Another record

The Pancaldi philosophy leaves nothing to chance, everything can be improved. Thus, work is done on installation and verification services to increase efficiency, maintenance, and upkeep.

During the year, Tecnocupole Pancaldi supplies skylights for the first Breeam-certified shopping centre in Italy.

2014

Men and machines

The mechanical processing department receives a sophisticated automated laser cutting system. Shortly after, a multi-year training plan for employees is initiated. More changes are on the way, and knowledge is always a good investment.

The sum of individual competencies is valuable for everyone.

2016

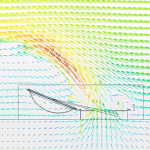

Pancaldi and UNIMORE

It's still research and development. It starts with analysing the behaviour of zenithal smoke and heat exhaust systems to improve their performance. But it's only the beginning.

2020

New milestones

What does the future hold? It's hard to say.

We rely on our capabilities and the guiding principles of Gianni and Luigi Pancaldi to interpret the upcoming changes in the best possible way.

In the meantime, we continue to design and build fixed skylights, operable skylights, and natural smoke and heat exhaust systems that are increasingly better, safer, and seamlessly integrated into building designs.